Struggling to shape metal efficiently? Traditional methods waste time and materials. Metal stamping solves this with precision and speed, transforming raw sheets into complex parts instantly.

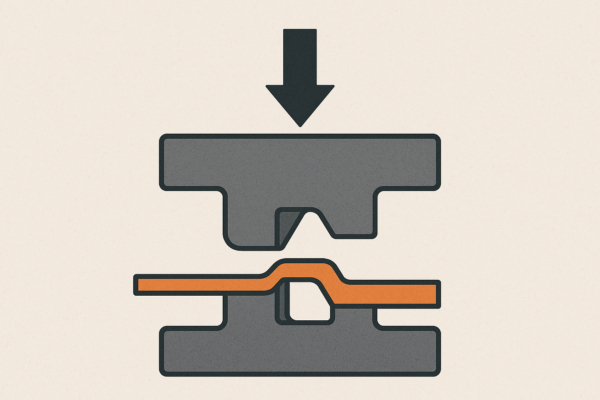

Metal stamping uses dies and presses to deform metal sheets. Force applied by the press shapes the metal into desired forms through cutting, bending, or stretching, ensuring high repeatability and accuracy.

To truly grasp metal stamping, let’s break down its machinery, methods, and variations. These insights will help you choose the right approach for your project.

How does metal stamping work?

Confused about how flat metal becomes intricate parts? The process seems magical, but it’s grounded in mechanical principles anyone can understand.

Metal stamping follows a systematic workflow: design validation ➔ material selection ➔ die setup ➔ stamping ➔ finishing. Each step ensures dimensional accuracy and structural integrity for mass production.

Key phases in metal stamping

| Step | Description | Tools Involved |

|---|---|---|

| 1. Design | CAD models validate part feasibility | Simulation software |

| 2. Die Making | Custom tools crafted for shaping | CNC machines, EDM |

| 3. Stamping | Press forces metal into die cavity | Hydraulic/mechanical press |

| 4. Finishing | Deburring, coating, or polishing | Grinders, plating tanks |

For example, automotive brackets require progressive dies1for multi-stage forming. At our factory. This method eliminates errors and reduces waste by 40% compared to manual fabrication.

What is the working principle of a stamping machine?

Ever wondered what powers metal stamping? The machine looks intimidating, but its core function is straightforward yet powerful.

A stamping machine converts rotational energy into vertical force. This force pushes the die into metal sheets, enabling cutting, bending, or embossing in one motion.

Components of a stamping press

| Part | Role |

|---|---|

| Frame | Supports vertical force up to 2,000 tons |

| Motor | Powers flywheel rotation |

| Clutch | Engages/disengages punch movement |

| Die Set2 | Custom tools for shaping metal |

Hydraulic presses3 excel at deep draws for sinks, while mechanical presses handle high-speed blanking for electrical contacts. Our factory uses servo-driven presses4 for 0.01mm precision, ideal for medical device components.

What are the 7 steps in the stamping method?

Feeling overwhelmed by the stamping process? Simplify it by following these seven stages, refined over decades of industrial practice.

From coil feeding to packaging, stamping includes: material prep ➔ alignment ➔ stamping ➔ trimming ➔ inspection ➔ finishing ➔ packaging. Automation ensures consistency across batches.

Detailed workflow

| Step | Action | Purpose |

|---|---|---|

| 1. Feeding | Uncoil metal sheet | Ensure steady material flow |

| 2. Alignment | Position sheet via sensors | Prevent misstrikes |

| 3. Stamping | Press shapes metal | Create base form |

| 4. Trimming | Remove excess edges | Achieve net shape |

| 5. Inspection | Check dimensions | Guarantee quality |

| 6. Surface Treat | Apply coatings | Enhance durability |

| 7. Packaging | Sort and protect parts | Ready for shipment |

For instance, smartphone shield production5 skips trimming by using fine-blanking dies6. Shows how skipping steps can reduce costs by 15%7.

What are the four types of metal stamping?

Choosing the wrong stamping type risks defects. Match your project to these four methods for optimal results.

Metal stamping variations include:

- Blanking (flat shapes)

- Piercing (holes/slots)

- Bending (angled forms)

- Deep Drawing (cups/enclosures)

Each suits specific geometries and volumes.

Method comparison

| Type | Usage | Tooling | Example |

|---|---|---|---|

| Blanking8 | Cut outlines | Punch and die | Washers |

| Piercing | Create holes | Sharp punches | Vent panels |

| Bending9 | Form angles | V-shaped dies | Brackets |

| Deep Drawing10 | Cylindrical parts | Multi-stage dies | Battery casings |

Blanking dominates 70% of our projects, like producing. However, deep drawing requires higher tonnage presses for seamless results.

Conclusion

Metal stamping transforms sheets into precise parts through force, custom dies, and systematic steps. Understanding presses, methods, and variations helps optimize production costs and quality for your needs.

-

Learn about progressive dies to see how they enhance efficiency and precision in metal stamping processes. ↩

-

Discover the importance of die sets in shaping metal, crucial for various manufacturing applications. ↩

-

Explore the benefits of hydraulic presses, especially for deep draws, to understand their role in efficient manufacturing processes. ↩

-

Learn how servo-driven presses achieve exceptional precision, making them ideal for high-quality medical device components. ↩

-

Explore this link to understand the innovative processes in smartphone shield production and how they enhance efficiency and cost-effectiveness. ↩

-

Learn about fine-blanking dies to see how they can streamline manufacturing processes and reduce costs significantly. ↩

-

Discover strategies and techniques that can lead to significant cost savings in manufacturing, enhancing your business's profitability. ↩

-

Explore this link to understand how blanking is a crucial process in manufacturing, dominating many projects. ↩

-

Discover the bending process in metal fabrication and its significance in creating various components, enriching your understanding of manufacturing. ↩

-

Learn about deep drawing's benefits and its applications in producing complex shapes, enhancing your knowledge of metal forming techniques. ↩